Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

Written by Elena Voss – 12 years European decorative glass market specialist, advised 600+ EU architects/retailers, certified REACH & CPR compliance auditor

If you’re a European architect, interior designer, or home improvement retailer, decorative glass panels are about to become your most competitive asset—if you get the trends and sourcing right. 2025 brings massive shifts in EU regulations, consumer preferences, and material innovations, and partnering with the wrong decorative glass manufacturer could leave you with non-compliant stock, missed sales, or costly fines.

Over 12 years working with 600+ European clients, I’ve seen businesses lose €5k-€30k because they ignored emerging trends or cut corners on manufacturer vetting. This guide isn’t just trend forecasting—it’s a actionable playbook built from real EU market experience. By the end, you’ll know exactly which decorative glass panels to stock, how to ensure full EU compliance, and how to partner with a top decorative glass manufacturer that delivers on trends, quality, and deadlines.

Why is this article worth your time? Here’s the value you’ll gain:

2025 isn’t just another year—it’s a chance to lead the market with innovative, compliant decorative glass panels. The key? Aligning your product selection with EU trends and partnering with a decorative glass manufacturer that understands the European market inside out. Let’s dive into the strategies that will make your 2025 a success.

European decorative glass market is projected to grow 8.3% in 2025, reaching €4.2B. The growth will be driven by three key trends—ignore them, and you’ll fall behind competitors who adapt.

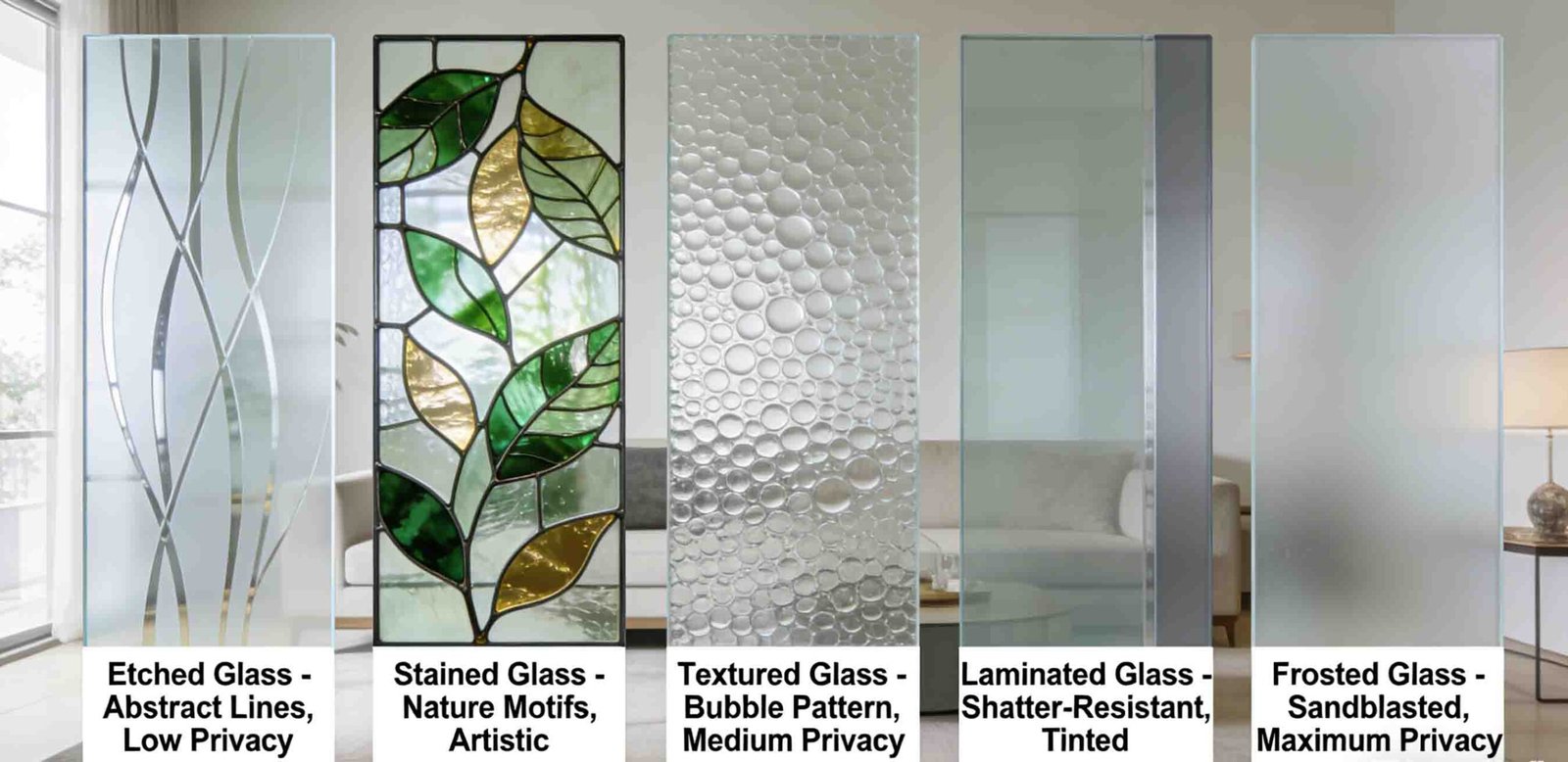

The EU decorative glass market is splitting into three high-demand segments:

| Market Segment | 2025 Growth Rate | Key Driver | Top Decorative Glass Type |

|---|---|---|---|

| Commercial Spaces (Hotels/Offices) | 11.2% | Post-pandemic renovation boom | Frosted gradient, smart glass |

| Residential (Home Renovation) | 7.8% | Sustainable living trends | Recycled glass, 3D texture |

| Architectural Facades | 6.5% | Energy efficiency regulations | Insulated decorative glass |

Key insight: Commercial spaces will drive the fastest growth—partner with a decorative glass manufacturer that specializes in large-scale projects.

These three styles will dominate EU markets in 2025—each with specific applications and customer appeal:

The #1 trend for commercial spaces: Gradual opacity transitions (clear to frosted) that balance privacy and natural light.

Residential market favorite: 3D raised patterns made from 80% recycled glass.

High-growth luxury segment: Glass with built-in LED lighting or privacy control.

EU regulations and consumer demand are driving two non-negotiable trends for any decorative glass manufacturer:

73% of EU consumers will pay 10-15% more for eco-friendly decorative glass panels (2024 EU Consumer Survey). Key requirements:

Decorative glass manufacturers are upgrading to 1200 DPI digital printers, enabling:

EU CPR regulations (2025 update) require all decorative glass panels for public spaces to:

2025 brings stricter EU regulations—non-compliant decorative glass panels will be seized at customs or recalled. A top decorative glass manufacturer will handle compliance for you, but you need to verify their credentials.

Your decorative glass manufacturer must hold these three certifications—no exceptions:

| Certification | Regulating Body | Critical Requirements | Verification Method |

|---|---|---|---|

| CE (CPR Regulation) | EU Commission | Structural safety, fire resistance, impact resistance | Check EU Construction Products Database |

| REACH Compliance | ECHA (European Chemicals Agency) | No SVHCs (197+ banned substances) | Request REACH SVHC Test Report (ISO 17025-accredited) |

| EU Ecolabel (Optional but Valuable) | EU Ecolabel Board | 60%+ recycled content, low carbon footprint | Verify on EU Ecolabel Portal |

Ignoring compliance isn’t worth the risk—here are two 2024 cases that highlight the dangers:

A Berlin-based home goods retailer imported 500 decorative glass panels from a non-compliant manufacturer. ECHA testing found lead (a banned SVHC) in the coating. Consequences:

A Spanish hotel ordered 200 frosted decorative glass panels for their lobby renovation. The panels failed CPR impact testing. Consequences:

CBAM will tax imported decorative glass panels based on their carbon footprint. To avoid extra costs:

Pro tip: A top decorative glass manufacturer will have CBAM-compliant production lines and can help you navigate the reporting requirements.

Don’t take a decorative glass manufacturer’s word for it—follow these 4 verification steps:

Choosing the right decorative glass panels for 2025 means balancing trends, compliance, and your specific market segment. Here’s how to make data-driven decisions that drive sales.

Your target customers dictate your product mix—use this breakdown to prioritize:

Commercial clients value durability, brand alignment, and compliance. Focus on:

Key question to ask your decorative glass manufacturer: “What’s your lead time for custom commercial orders?” (Top manufacturers deliver in 2-3 weeks.)

Homeowners prioritize aesthetics, sustainability, and affordability. Focus on:

Key question to ask your decorative glass manufacturer: “What’s the warranty on your residential panels?” (Aim for 5+ years.)

Each 2025 trend has unique selection criteria—here’s how to pick the best options:

Avoid these common mistakes when selecting frosted gradient decorative glass panels:

Selection checklist for frosted gradient panels:

Not all recycled glass is created equal—use this test to evaluate samples:

Smart decorative glass panels require extra due diligence:

Pro tip: Choose a decorative glass manufacturer that offers installation support—smart glass requires specialized setup.

Over the years, I’ve seen clients make these 3 avoidable mistakes—don’t repeat them:

A Portuguese interior designer ordered 100 3D textured panels for a restaurant. The deep grooves trapped food and grease, leading to 50% returns. Solution: Choose textured panels with shallow, easy-to-clean patterns for commercial food spaces.

A Dutch retailer bought cheap decorative glass panels from a non-compliant manufacturer. They saved 20% upfront but paid €8k in fines. Solution: Never prioritize price over CE/REACH certification.

A Swedish architect used non-insulated decorative glass panels for a building facade. High energy bills led to a lawsuit. Solution: For cold EU countries, choose insulated panels with low U-values.

The right decorative glass manufacturer isn’t just a supplier—they’re a strategic partner that helps you capitalize on 2025 trends and avoid compliance risks. Here’s how to find and collaborate with the best.

Use these 5 non-negotiable criteria to evaluate potential manufacturers:

Look for a manufacturer with:

A top decorative glass manufacturer will:

Verify that the manufacturer:

For competitive advantage, your manufacturer should:

Look for:

Clear communication avoids costly mistakes—use this framework when working with your decorative glass manufacturer:

Provide these 5 key pieces of information upfront:

Follow this 3-step sample process to ensure alignment:

Ask for:

Negotiate these key terms to protect your business and maximize value:

For small to medium businesses:

Fair pricing structure for EU clients:

30% Deposit (after sample approval) + 60% Balance (against B/L copy) + 10% Holdback (released after 7 days of delivery)

Why holdback? It gives you time to inspect the order and report defects before full payment.

Choose DAP (Delivered at Place) terms—your manufacturer covers:

Negotiate:

These real-world examples show how partnering with a top decorative glass manufacturer and aligning with 2025 trends drives growth.

Background: A mid-sized German hotel chain (12 locations) wanted to renovate lobbies to attract business travelers. They partnered with a leading decorative glass manufacturer specializing in commercial projects.

Need to balance privacy (for meeting areas) and natural light (for open lobbies), while complying with EU CPR regulations for public spaces.

Collaborated with the decorative glass manufacturer to:

Key takeaway: Custom trend-aligned panels differentiate commercial spaces and drive customer satisfaction.

Background: A Swedish home improvement retailer wanted to expand their sustainable product line to meet EU consumer demand.

Find a decorative glass manufacturer that could produce affordable 3D textured panels with 80% recycled content, EU Ecolabel certification, and quick lead times.

Partnered with a manufacturer offering:

Key takeaway: Sustainable trends + compliance = sales growth and competitive advantage in residential markets.

The three most profitable trends are frosted gradient panels (commercial spaces), 3D textured recycled glass (residential), and smart integrated glass (luxury segment). These trends align with EU regulations, consumer demand, and market growth projections—partnering with a decorative glass manufacturer that specializes in these styles will maximize your ROI.

Verify REACH compliance in three steps: 1) Request an ISO 17025-accredited SVHC test report (lists all substances present); 2) Check the manufacturer’s name in ECHA’s REACH registration database; 3) Ask for references from EU clients who have passed ECHA audits. Avoid manufacturers that only provide in-house test reports—they’re not credible.

Costs vary by style and thickness: Frosted gradient (€45-€75 per m²), 3D textured recycled (€35-€60 per m²), smart glass (€150-€250 per m²). Working directly with a decorative glass manufacturer (not a middleman) saves 15-25%. Volume discounts apply—orders over 200 units typically get 10-15% off.

Top decorative glass manufacturers deliver custom samples in 5-7 days and bulk orders in 2-3 weeks (production) + 1-2 weeks (shipping to EU ports). Total lead time: 3-5 weeks. Rush orders (1-2 week production) are available for a 20-30% premium. Always add a 1-week buffer for customs clearance.

Ecolabel isn’t mandatory, but it’s highly recommended. 73% of EU consumers prefer Ecolabel-certified products, and many retailers (e.g., IKEA, Leroy Merlin) require it for shelf space. A reputable decorative glass manufacturer can help you obtain Ecolabel certification if their panels meet the 60%+ recycled content and low-carbon requirements.

First, document the issue with photos/videos within 7 days of delivery. Contact your decorative glass manufacturer with the evidence and request a replacement. Top manufacturers will send replacements within 10 days and cover shipping costs. For non-compliant panels, they should provide a full refund or rework the order to meet EU standards. Always include these terms in your contract.

Yes—top manufacturers provide EU-specific installation guides (in English, German, French, Spanish) that comply with local building codes. Many also offer virtual installation support or can recommend EU-based installation partners. For complex projects (e.g., smart glass), some manufacturers provide on-site training for your team.

Ready to dominate the 2025 European decorative glass market? Download our exclusive 2025 EU Decorative Glass Trend & Compliance Guide to:

Download Free Guide + Request Custom Sample

At Havenseek Mirror, we’ve helped 600+ EU businesses partner with top decorative glass manufacturers and capitalize on emerging trends. Our team of EU compliance experts and market specialists will guide you every step of the way—from trend selection to order delivery. Claim your free guide today and start winning in 2025.

2025 is a pivotal year for European decorative glass—trends are shifting, regulations are tightening, and consumers are demanding more sustainable, innovative products. The key to success is simple: align your decorative glass panels with high-growth trends and partner with a top decorative glass manufacturer that understands the EU market.

By following the strategies in this guide, you’ll avoid compliance pitfalls, reduce sourcing time, and offer products that your customers actually want to buy. Whether you’re targeting commercial spaces with frosted gradient panels or residential markets with recycled 3D glass, the right manufacturer will deliver quality, compliance, and trend alignment—all while supporting your business goals.

Remember: The European decorative glass market is growing, but only businesses that adapt will thrive. Don’t wait until 2025 is halfway through—start planning today. Contact Havenseek Mirror now to connect with our network of EU-compliant decorative glass manufacturers, request custom samples, and download your free trend guide. Your 2025 success story starts here.